EPG Pumps - Suitable for Class I, Division 1 & 2 Locations

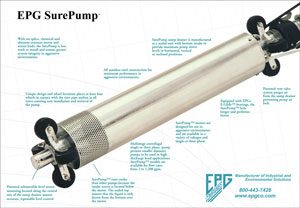

EPG’s SurePump™ Vertical Sump Drainer (VSD) pumps contaminated liquids for recovery, leachate collection, gas condensate removal, and sampling applications. It can be used in aggressive environments. Other designs may fail while EPG Vertical Sump Drainers are still going strong.

The SurePump™ pump is a completely sealed unit with bottom inlet, built with stainless steel for harsh environments and unlike competitor models, draws liquid over or past the entire motor to maximize cooling and extend pump life.

EPG backs the vertical sump drainers with a one year warranty effective the date of installation.

- Stainless steel construction

- Corrosion resistant E-Glide™ bearings and seal rings for extra durability

- Sealed unit with liquid flow drawn past motor for cooling

- Facilitates draw-down to the very bottom of the vessel

- Chemical resistant jacketed, no-splice, CP motor lead

- Vent valve system purges air from the sump drainer preventing pump air lock

- Flow rates available from 2 – 1,200 gpm

- UL listed control panels are available for simple, trouble-free control

| Series | Flow Range | Nominal Flow |

|---|---|---|

| Series - 2 | 1-14 GPM | 10 GPM |

| Series - 3 | 10-20 GPM | 15 GPM |

| Series - 5 | 15-30 GPM | 25 GPM |

| Series - 7 | 20-50 GPM | 35 GPM |

| Series - 9 | 20-50 GPM | 45 GPM |

| Series - 11 | 35-80 GPM | 62 GPM |

| Series - 14 | 45-95 GPM | 77 GPM |

| Series - 18 | 20-120 GPM | 85 GPM |

| Series - 31 | 50-200 GPM | 150 GPM |

| Series - 47 | 75-300 GPM | 230 GPM |

| Series - 61 | 50-400 GPM | 300 GPM |

| Series - 77 | 75-500 GPM | 385 GPM |

| Series - 95 | 95-680 GPM | 475 GPM |

| Series - 125 | 125-850 GPM | 625 GPM |

| Component | Standard | 316 Stainless Steel |

|---|---|---|

| Check Valve Housing | 304 Stainless Steel | Special Order |

| Check Valve | 304 Stainless Steel | Special Order |

| Check Valve Seat | E-Glide™ | Special Order |

| Diffuser Chamber | 304 Stainless Steel | Special Order |

| Impeller Seal Ring | E-Glide™ | Special Order |

| Impeller | 304 Stainless Steel | Special Order |

| Motor Adapter | 304 Stainless Steel | Special Order |

| Inlet Screen | 304 Stainless Steel | Special Order |

| Pump Shaft | 304/431 Stainless Steel | Special Order |

| Coupling | 329/420/431 Stainless Steel | Special Order |

| Fasteners | 304 Stainless Steel | Special Order |

| Bearings | E-Glide™ | Special Order |

| Component | 1/3 to 2 Horsepower Pollution Recovery | 3 to 60 Horsepower Sandfighter |

|---|---|---|

| End Bell Castings | 304 Stainless Steel over Iron | 304 Stainless Steel over Iron |

| Stator Shell | 301 Stainless Steel | 301 Stainless Steel |

| Shaft Extension | 303 Stainless Steel | 303 Stainless Steel |

| Fasteners | 316 Stainless Steel | 300 Stainless Steel |

| Seal Cover | Tefzel | Sintered Bronze |

| Shaft Seal | Viton | Viton, Carbon, Ceramic Face Seal |

| Diaphragm | Viton | Nitrile Rubber |

| Diaphragm Plate | 304 Stainless Steel | 304 Stainless Steel |

| Diaphragm Spring | 302 Stainless Steel | 302 Stainless Steel |

| Diaphragm Cover | 316 Stainless Steel | 304 Stainless Steel |

| Slinger | Viton | Nitrile Rubber |

| Lead Sleeve | 316 Stainless Steel | 316 Stainless Steel |

| Lead Jam Nut | 316 Stainless Steel | N/A |

| Lead Jam Clamp | N/A | N/A |

| Lead Potting | Epoxy | Epoxy |

| Lead Bushing | Viton | Viton |

| CP Cable | SBR Rubber | SO Neoprene | PVC | |

|---|---|---|---|---|

| Unaged Physicals | ||||

| Tensil Strength (psi) | 2500 | 1420 | 1630 | 1410 |

| 100% Modulus (psi) | 340 | 690 | 770 | 780 |

| Elongation (%) | 650 | 300 | 300 | 330 |

| Low Temperature Properties | ||||

| Brittle Point (°F) | < -100 | -52 | -38 | -32 |

| Cold Bend @ -35°C | Pass | Pass | Pass | Pass |

| Cold Bend @-50°C | Pass | Pass | Fail | Fail |

| Cold Bend @-65°C | Pass | Fail | Fail | Fail |

| Aging Properties | ||||

| - Air Oven 7 days @ 121°C | ||||

| % Retention of Tensile | 107 | 104 | 188 | 124 |

| % Retention of Elongation | 115 | 17 | 17 | 0 |

| - Air Oven 7 days @ 136°C | ||||

| % Retention of Tensile | 97 | 0 | 0 | 0 |

| % Retention of Elongation | 90 | 0 | 0 | 0 |

| - Air Bomb 42 hrs @ 127°C | ||||

| % Retention of Tensile | 88 | 56 | 93 | 97 |

| % Retention of Elongation | 113 | 18 | 43 | 83 |

| - Oxygen Bomb 7 days @ 80°C | ||||

| % Retention of Tensile | 98 | 118 | N/A | 109 |

| % Retention of Elongation | 93 | 87 | N/A | 94 |

| Ozone Resistance | ||||

| Hours to Cracking | ||||

| (100 pphm/100°F) | >1000 | 24 | N/A | >1000 |

| Heat Deformation (T2/T1) | ||||

| 2000 gms @ 121°C | .86 | .93 | .95 | .70 |

| Mechanical Properties | ||||

| Crushing Strength | ||||

| - lbs force to failure | 3400 | 2000 | N/A | 3000 |

| Abrasion Resistance (Uniroyal) | ||||

| - cycles to wear thru jacket | 36 | 18 | 14 | 43(1) |

| (1) Material Coated Abrasive Wheel | ||||

| Chemical Resistance | ||||

| Water Resistance | E | G | G | E |

| Acid Resistance | E | G | G | G |

| Alkali Resistance | E | G | G | G |

| Aliphatic Resistance (gasoline, kerosene) | E | A | A | G |

| Aromatic Hydrocarbons (benzol, toluol) | E | A | A | A |

| Oil | E | A | A | E |

| Legend: E = Excellent G = Good A = Average | ||||

| Ratings based on average performance of general purpose compounds. | ||||

Other EPG Pumps:

Horizontal Wheeled Sump Drainer

Pump Curves:

To obtain more information or a copy of a pump curve, please email us or call us at 800-443-7426.

** Teflon is a registered trademark of DuPont.

The SurePump Wheeled Sump Drainer is protected by U. S. patent #4,966,534 and #4,992,030. Additional patents pending.

SurePump™ Vertical Sump Drainer

SurePump™ Vertical Sump Drainer