EPG Companies Flow Sensor uses a special axle and dual magnet drum design that takes the magnets out of the paddles. One major problem with most paddlewheel-type flow sensors having magnets in the paddles is that metal particles tend to stick to the magnets. The collecting material then causes a change in the flow characteristics in the paddle. EPG's dual magnetic drum design, with rapidly changing polarity and fluid velocity, causes the metallic particles to drop off into the flow stream and then are swept away.

Features:

- Low cost

- 2 year warranty

- High reliability

- High sensitivity

- Wide range 2 – 10,000 GPM

- Pipe sizes from 1″ and greater

- Patented six blade, non-magnetic design

- Available in Delrin or Kynar

- One paddle wheel fits ALL SIZES

- Transmits up to 1,000 feet without the need for additional amplifiers

- Direct logic pulse output

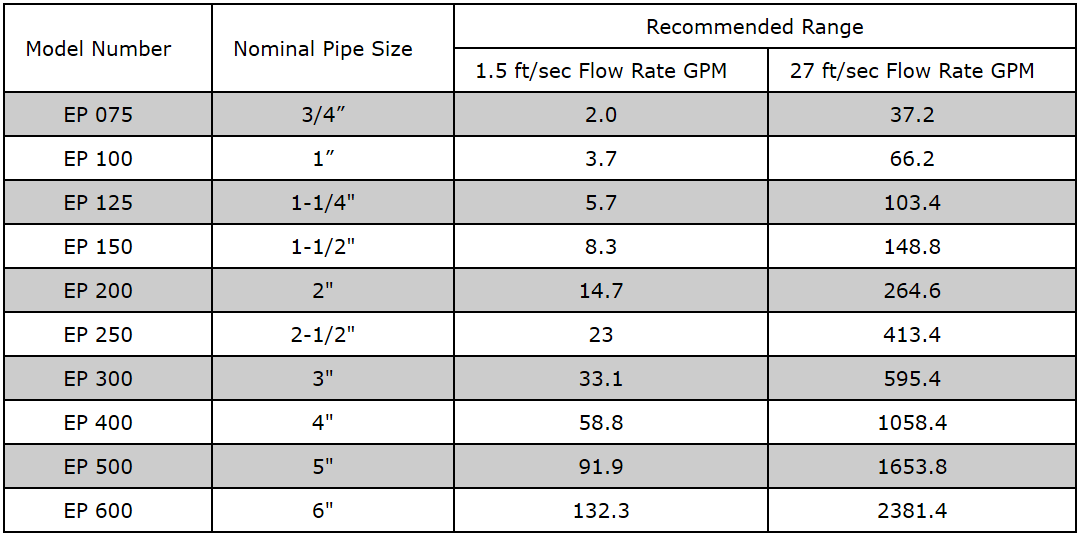

- Flow velocities range of 1.5 to 27 fps

- Operating pressure to 200 PSIG

- Liquid temperatures to 250° F

For more liquid flow system components, see:

Monitoring Systems and Components

For more information, please call

EPG Companies Inc.

INSTALLATION HINTS

- Pipe must be full for accurate reading.

- Minimum velocity is 1.5 ft./second. Recommended maximum velocity is 27 ft./second. The flow must be uniform at the point where the flow sensor is installed or an incorrect reading will result.

- To accommodate a uniform flow, allow at least ten (10) pipe diameters upstream and five (5) pipe diameters downstream of the flow sensor. Non-uniform flow is often caused by elbows, partially open valves or an increase in pipe diameter.

EPG E-Series Liquid Flow Sensor

EPG E-Series Liquid Flow Sensor