Landfill gas is a factor at all landfills. Inaccurate and unreliable level monitoring and control are often the result. We call this Landfill Gas Effect.

One effect is the accumulation of positive pressure in the sump or riser. The level sensor reads more liquid than is actually present. The pump will start too soon and shut off too late or run dry.

If a gas collection system is installed this can place sumps or risers under negative pressure or vacuum. This can result in a lower level reading than is present, allowing more liquid to accumulate before the pump turns on.

Worst case is where the pressure fluctuates from plus to minus. This pulsing will cause the pumps to turn on and off rapidly and possibly to run dry. It also creates problems with the level data.

The following video clips will illustrate and demonstrate those conditions using EPG's LFG Demo Unit. Our proven solution is the BJBGE-100B junction box. When connected directly to the sump, this breakout box compensates for and neutralizes the gas effect.

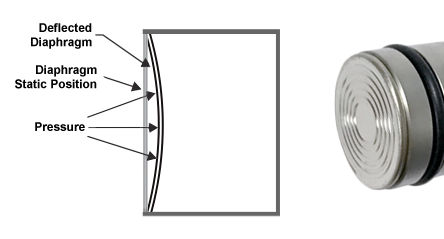

A level sensor or pressure transducer utilizes a very thin diaphragm to measure liquid levels. The force applied to the diaphragm can be amplified from positive pressure or reduced by vacuum. The result is inaccurate and unreliable level readings.

Demonstrating Effect of Vacuum and Pressure on Level Sensor/Meter

Media error: Format(s) not supported or source(s) not found

mejs.download-file: https://www.epgco.com/wp-content/uploads/2018/08/lfgdemo-082718.mp4?_=1mejs.download-file: https://www.epgco.com/wp-content/uploads/2018/08/lfgdemo-082718.mp4?_=1Demonstrating Effect of Vacuum and Pressure on Level/Pump Control

Media error: Format(s) not supported or source(s) not found

mejs.download-file: https://www.epgco.com/wp-content/uploads/2018/08/lfgriserdemo-082718.mp4?_=2mejs.download-file: https://www.epgco.com/wp-content/uploads/2018/08/lfgriserdemo-082718.mp4?_=2 Landfill Gas Effect Overview

Landfill Gas Effect Overview