"L" Series Controllers Function and Description:

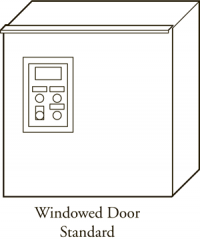

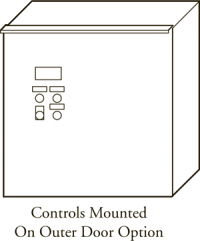

EPG Companies Inc., "L" Series PumpMaster controllers are UL listed 508A/698A, designed to operate a pump motor(s) and auxiliary equipment in manual or automatic mode. The enclosures are equipped with a window in the outer door, an inner door, a stainless steel drip shield, and a tamper resistant latch. The NEMA 4 (standard) enclosures are finished with polyester urethane paint. The NEMA 4X (optional) enclosures can be either stainless steel or non-metallic. *Note: For more detailed and complete Engineer’s Specifications, see individual bulletins listed below. For Pump Control Panel Dimensions see Builletin 6010. For troubleshooting see, Major Causes of Pump and Control Problems at Landfills.

The L800F PumpMasterTM is designed to start and stop a pump and annunciate a high level alarm using three float level sensors. The pump starts when the start float is displaced and continues to run until the liquid level decreases to the stop float sensor. If the liquid level rises beyond the pump start float to a high level float, a high level alarm will be annunciated. For further information, see Bulletin 0053b for single phase and Bulletin 0055a for three phase.

The L825 PumpMasterTM is designed to control a submersible pump using a load monitor. During each run cycle, the pump draws liquid from the sump down to the pump intake. The load monitor detects the unloaded condition and stops the pump. It allows the pump to run for a few seconds while it checks the load. If the pump is running within the preset range, it completes the next cycle. If not, it will go through another off delay period. For further information, see Bulletin 0095a for single phase and Bulletin 0096a for three phase.

The L850F PumpMasterTM is designed to operate two pumps in lead/lag alternating mode. The lead pump starts upon change in liquid level as sensed by a start level float sensor. The pump will continue to run until the level reaches the stop level float sensor. The lag pump will start if the liquid level continues to rise above the start level float to a second start level float and both will continue to run until the liquid level decreases to the stop level float sensor. If the liquid level rises to the high level float, a high level condition will be annunciated. If a motor trips while running due to an overload condition, the other pump will start automatically. The electric alternator provides equalized wear and usage of each pump by alternating successive starts. For further information, see Bulletin 0083a for single phase and Bulletin 0085b for three phase.

The L875 PumpMasterTM is designed to control two or more (optional) submersible pumps using load monitors. During each run cycle, the pump draws liquid from the sump down to the pump intake. The load monitor detects the unloaded condition and stops the pump. It allows the pump to run for a few seconds while it checks the load. If the pump is running within the preset range, it completes the next cycle. If not, it will go through another off delay period. For further information, see Bulletin 0114a for single phase and Bulletin 0115b for three phase.

The L900LO PumpMasterTM is designed for use at leachate transport truck loading facilities. It combines a storage tank level sensor, volume batch controller, flow sensor input, remote start/stop pendant, and transport truck overfill protection to provide easy, worry-free loading of leachate transport trucks. The operator enters the number of gallons to be pumped using the flow meter keypad and presses the run (start) button. The meter has a backlit LCD display of values. When the desired number of gallons have been pumped, the pump stops. The controller is reset and ready for the next loading operation. A stainless steel truck tank high level sensor with bracket easily attaches to the top of the transport truck to prevent overfilling. For further information, see Bulletin 1020c for single phase and Bulletin 1025a for three phase.

The L925PT PumpMasterTM is designed to start and stop a pump using the LevelMasterTM level control meter with a submersible pressure transmitter. The pump starts at the pump start level set point and continues to run until the liquid level decreases to the pump stop level set point as programmed in the LevelMaster level control meter. If the liquid level rises to the high level alarm set point, a high level alarm will be annunciated. If the level meter fails and rises to the high-high level fail-safe set point, the pump motor will shut off. For further information, see Bulletin 0050c for single phase and Bulletin 0060b for three phase.

The L925PTG PumpMasterTM is designed to operate a pump when connected to a generator. A power monitor will monitor over and under voltage. It will shut off the pump to prevent damage that may occur as a result of fluctuations in power supply voltage beyond acceptable limits. The controller will start and stop a pump using the LevelMaster level control meter with a submersible pressure transmitter. The pump starts at the pump start level set point and continues to run until the liquid level decreases to the pump stop level set point as programmed in the LevelMaster level control meter. If the liquid level rises to the high level set point, a high level will be annunciated. If the level meter fails and rises to the high-high level fail-safe set point, the pump motor will shut off. For further information, see Bulletin 0740b for single phase and Bulletin 0745a for three phase.

The L930PT PumpMasterTM is designed to start and stop a pump using the LevelMaster level control meter with a submersible pressure transmitter. The pump starts at the pump start level set point and continues to run until the liquid level decreases to the pump stop level set point as programmed in the LevelMaster level control meter. If the liquid level rises to the high level alarm set point, a high level alarm will be annunciated. If the liquid level decreases to the low level alarm set point, a low level alarm will be annunciated. For further information, see Bulletin 0065a for single phase and Bulletin 0066a for three phase.

The L950PT PumpMasterTM is designed to operate two pumps in lead/lag alternating mode. The electric alternator provides equalized wear and usage of each pump by alternating successive starts. The lead pump starts at the pump start level set point and continues to run until the liquid level decreases to the pump stop level set point as programmed in the LevelMaster level control meter. The lag pump will start after the lead pump starts if the liquid level continues to rise above the pump start level set point and both pumps will continue to run until the liquid level decreases to the pump stop level set point as sensed by the pressure transmitter. If the liquid level rises to the high level alarm set point, a high level alarm will be annunciated. If a motor trips while running due to an overload condition, the other pump will start automatically. For further information, see Bulletin 0070b for single phase and Bulletin 0080b for three phase.

The L960PT PumpMasterTM is designed to operate two pumps in lead/lag alternating mode and a third independent pump. In the lead/lag mode, the lead pump starts upon change in liquid level as sensed by a pressure transmitter. The pump will continue to run until the level decreases to the pump stop level set point. The lag pump will start if the liquid level continues to rise above the pump start level set point and will continue to run until the liquid level decreases to the pump stop level set point as sensed by the pressure transmitter. If the liquid level rises to the high level set point, a high level will be annunciated. If a motor trips while running due to an overload condition, the other pump will start automatically. The electric alternator provides equalized wear and usage of each pump by alternating successive starts.

The third independent pump is designed to start upon the change in liquid level as sensed by a pressure transmitter. The pump will continue to run until the pump stop level set point is reached. If the liquid level rises to the high level set point, a high level will be annunciated. If the level meter fails and rises to the high-high level fail-safe set point, the pump motor will shut off. For further information, see Bulletin 0150b for single phase and Bulletin 0160b for three phase.

The L975PT PumpMasterTM is designed to operate two pumps or more (optional) upon independent changes in liquid levels as sensed by individual pressure transmitters. Each pump will start at the pump start level set point and will continue to run until the liquid level decreases to the pump stop level set point as sensed by the pressure transmitter. If the liquid rises to the high level alarm set point, a high level alarm will be annunciated. If the liquid level rises to the high-high level fail-safe set point, the pump motor will shut off. For further information, see Bulletin 0091b for single phase and Bulletin 0100b for three phase.

PumpMaster™ Controllers – Engineer’s Specifications

PumpMaster™ Controllers – Engineer’s Specifications