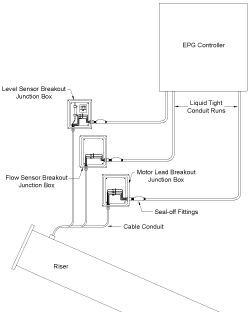

Control failure and expensive repairs, caused by methane gas and moisture are real and potentially dangerous possibilities. To simplify maintenance and repair and increase the safety and accuracy of your system, simply install an EPG Breakout Junction Box between your pump and control panel.

EPG Breakout Junction Boxes are a simple and convenient way to disconnect power or sensor wires during maintenance and/or repair work and create a gas-tight seal between your riser, well or sump and your control panel.

Landfill gases migrating through motor and sensor cable conduit to the controller is one of the largest contributors to early control panel failure. Not only can these gases increase the chance for explosions, they can also corrode the contacts and make wires brittle. Give your system a break! Install an EPG Breakout Box close to the side slope riser and then hardwire the breakout box to the controller. EPG Breakout Boxes - a break you need for optimum landfill operation!

- Seals off harmful migrating gas

- Equipped with FNPT waterproof exit hub

- Minimizes costs by running shorter motor or sensor cable

- Available in a variety of configurations for one or more devices

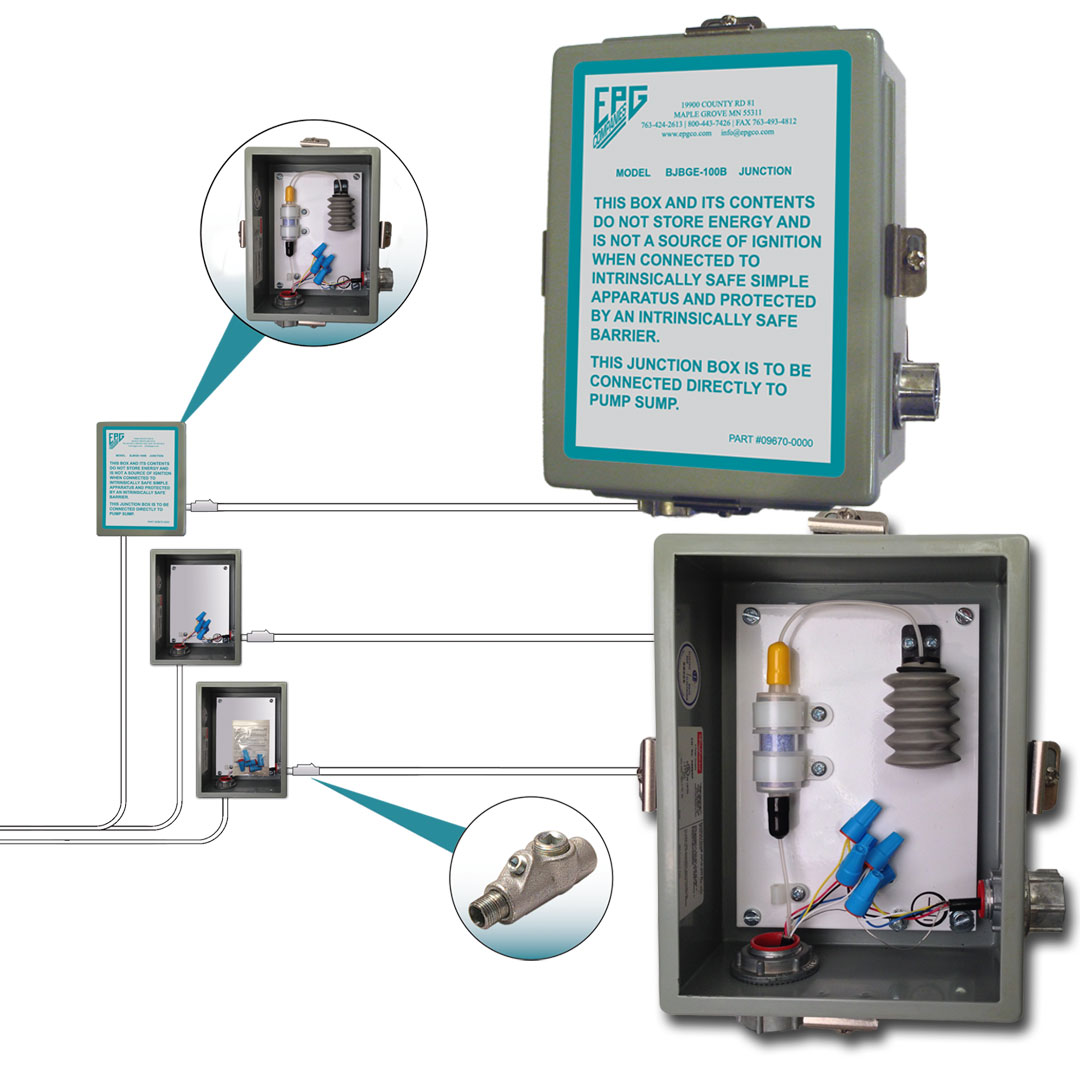

- Weatherproof NEMA4X enclosure with dryer tube and bellows to seal out moisture

Standard Models: NEMA 4X (Non-Metallic)

BJBGE-100B: NEMA 4X (Powder Coated Steel)

Also Available: NEMA 4X (Stainless Steel), NEMA 7/4 (Explosion-proof/weathertight)

* Each level sensor includes a desiccant dryer and bellows mounted inside the enclosure.

| Model Number | Description |

|---|---|

| BJBGE-100B | Landfill Gas Effect |

| BJBD100 | Leak Detection |

| BJBF400 | Float |

| BJBF425 | Two (2) Floats |

| BJBF440 | Three (3) Floats |

| BJBF450 | Four (4) Floats |

| BJBF460 | Five (5) Floats |

| BJBF700 | Flow Sensor |

| BJBF725 | Two (2) Flow Sensors |

| BJBF750 | Three (3) Flow Sensors |

| BJBS470 | Four (4) Temperature Sensors |

| BJBL600B | Level Sensor* |

| BJBL600BT | Level Sensor* (Tank Gauging) |

| BJBL600BVA | Level Sensor* (Vacuum Application At Riser) |

| BJBL625B | Two (2) Level Sensors* |

| BJBO800B | Level Sensor & Flow Sensor* |

| BJBO800BT | Level Sensor & Float* (Tank Gauging) |

| BJBO815B | Level Sensor & Float* |

| BJBO825B | Two (2) Level & One (1) Flow Sensor* |

| BJBO850B | One (1) Level & Two (2) Flow Sensors* |

| BJBO900B | Two (2) Level & Two (2) Flow Sensors* |

| BJBO905B | Level Sensor, Flow Sensor & Leak Detection Sensor* |

| BJBO925B | Two (2) Level & Two (2) Leak Detection Sensors* |

| BJBP300 | Two (2) Probes |

| BJBP315 | Three (3) Probes |

| BJBP325 | Four (4) Probes |

| BJBP500 | Motor Lead (14 to 10 AWG) |

| BJBP500KSB | Motor Lead (KSB Motor) |

| BJBP500SP | Motor Lead (Large Cables) |

| BJBP525 | Two (2) Motor Leads (14 to 10 AWG) |

| BJBP550 | Three (3) Motor Leads (14 to 10 AWG) |

*Each level sensor includes a desiccant dryer and bellows mounted inside the enclosure.

Breakout Junction Boxes

Breakout Junction Boxes